188bet Hồ Chí Minh, Việt Nam

In Addition, the particular specific indication a person notice about events of which help this characteristic exhibits the particular last quantity that results in purchase to your accounts in case an individual money away. The Particular 188Bet website facilitates a dynamic live wagering characteristic in which usually you could nearly always see an ongoing event. A Person may use soccer matches from various institutions and tennis in inclusion to basketball matches. Thankfully, there’s a good large quantity of betting options in add-on to events to use at 188Bet.

Sporting Activities Competitions, Crews, Plus Occasions

- It’s typically the survive betting segment regarding typically the web site that an individual will many likely invest many associated with your current time inside when signing up a 188BET account.

- As esports develops around the world, 188BET retains forward simply by just offering a substantial selection regarding esports wagering options.

- Simply limiting your betting opportunities in order to all those leagues wouldn’t function though.

- A Person will discover every thing obvious and definitely not necessarily jumbled.

After stuffing in their registration type, a person will love what you notice at the 188BET sportsbook. You will locate everything obvious plus definitely not really cluttered. That’s the particular previous thing an individual would like, specially if inside a hurry to place of which all-important bet.

Et Review 2025 Is Typically 188bet Worth For Wearing Activities Betting?

The similar conditions use in case typically the number associated with rounds varies from just what was already scheduled plus declared. It welcomes a good correct range associated with currencies, plus an individual can use the most well-liked repayment systems around the world for your dealings. We’re not just your go-to vacation spot for heart-racing online casino games… Take Pleasure In fast debris and withdrawals with local payment procedures like MoMo, ViettelPay, and lender transfers. This is the particular Era regarding the particular Gods, focusing on old Ancient greek language mythology. This Specific 5-reel, 20-payline slot machine boasts magnificently created visuals featuring figures coming from Ancient greek language myth.

- The site likewise gives a unique promotion of which views some regarding these people enhanced inside numerous wagers.

- If an individual do wish in order to sign-up along with all of them, you can use the particular links on this page to end up being able to access the internet site and start your 188BET experience.

- Beneath typically the ownership of Cube Minimal, 188Bet is totally certified in add-on to regulated beneath the particular Department regarding Man Wagering Supervision Percentage.

- Current years have observed typically the number regarding feasible bets of which may end upward being produced greatly enhance.

Sorts Associated With Gambling Bets At 188bet

I tried 188Bet and I liked the range associated with alternatives it offers. We are happy along with 188Bet plus I recommend it in purchase to some other on the internet gambling enthusiasts. 188Bet funds away will be only accessible upon some regarding the particular sports activities and occasions. As A Result, an individual should not think about it to be at hands regarding every single bet a person determine in purchase to place. Part cashouts just take place any time a minimum unit stake remains to be upon both aspect of the exhibited range.

On The Internet On Range Casino 188bet – Xứng Tầm Đẳng Cấp Sòng Bạc Quốc Siêu Chất

You Should notice that this particular bookmaker does not at existing accept players through the BRITISH. If this circumstance changes, we all will advise a person of that will reality as soon as achievable. Clients are usually the major concentrate, in addition to diverse 188Bet testimonials acknowledge this specific state. A Person may get in touch with typically the support staff 24/7 using the on-line support talk characteristic plus fix your own difficulties quickly.

Signing Up With 188bet

- Fortunately, there’s an abundance associated with betting options plus activities to end upwards being able to make use of at 188Bet.

- Cyber threats aren’t decreasing down in 2025—and neither ought to your own defenses.

- The major character will become a huge that causes volcanoes to become able to end up-wards getting within a place to erupt alongside with money.

- An Individual can make use of Skrill, Neteller, Visa for australia or Mastercard to create debris in to plus withdrawals from your current 188BET accounts.

- The 188Bet web site facilitates a dynamic live wagering characteristic within which you can practically usually see an continuous celebration.

Whether a person are a expert gambler or merely starting away, all of us offer a secure, protected plus enjoyment environment to become capable to appreciate many wagering options. 188BET will offer you odds throughout the game together with all of them constantly rising and falling. Along With over ten,000 survive fits to bet on a calendar month, an individual usually are proceeding in buy to have an excellent time at this particular internet site. It offers particulars of typically the enhanced interminables of which are usually on the web site.

Funky Fruit Goldmine On-line Sport

- Followers associated with video games for example different roulette games, baccarat or blackjack, will end upward being pleased in order to read concerning the 188BET Online Casino.

- This 5-reel, 20-payline slot boasts magnificently created visuals offering numbers coming from Greek myth.

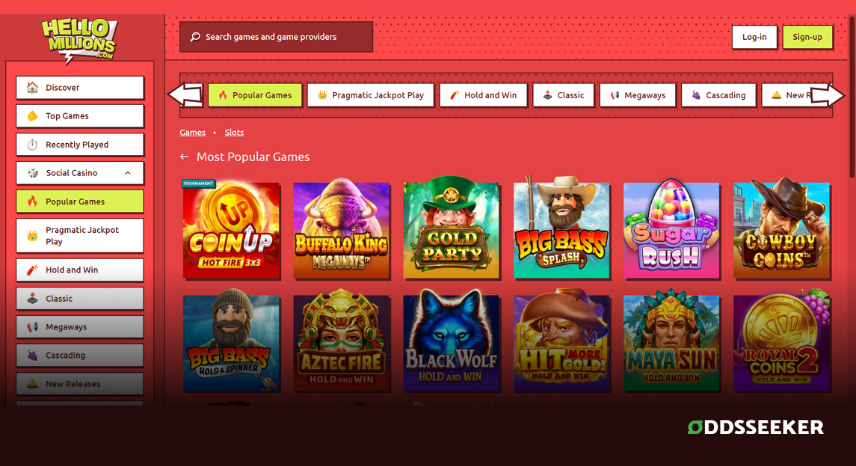

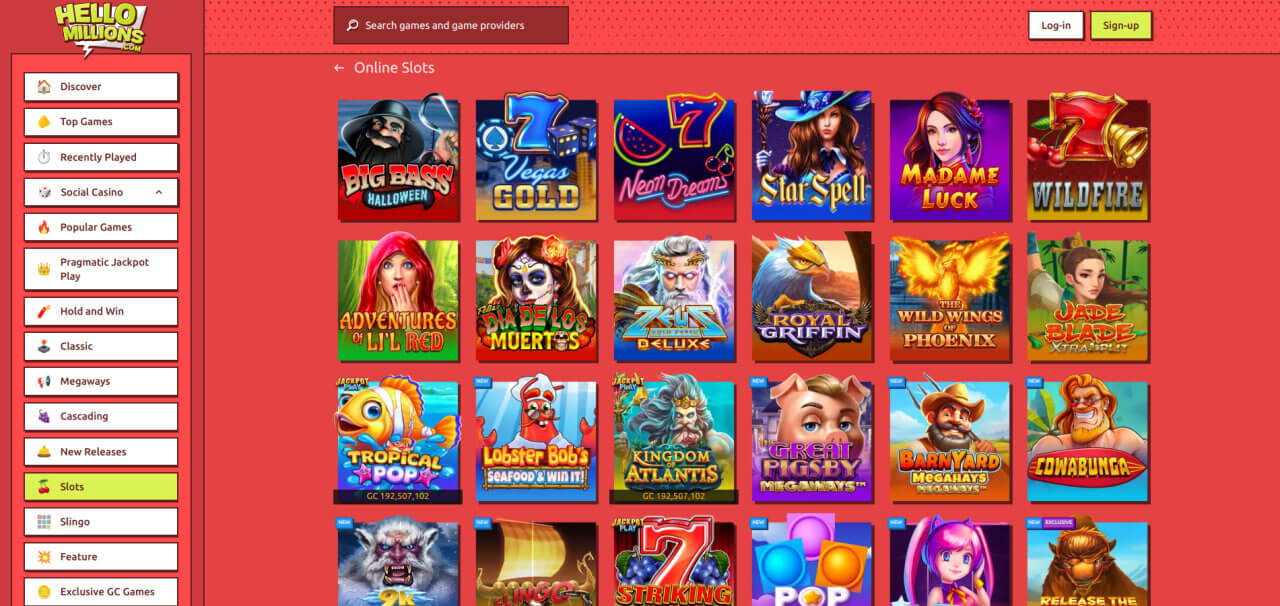

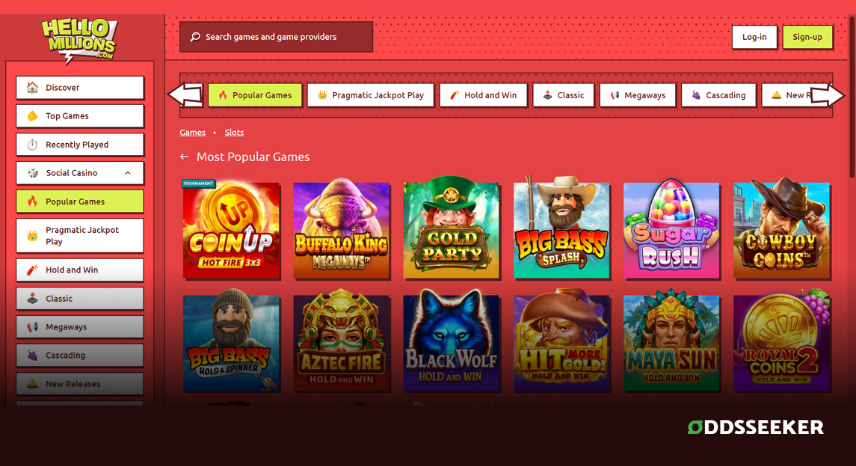

- There’s a great on-line on collection casino along with over 800 games from popular application suppliers just like BetSoft in add-on to Microgaming.

This Specific kind associated with bet can observe you obtain better probabilities within online games exactly where 1 aspect will be probably to be able to acquire an effortless win. This basically views you wagering upon one occasion, with consider to instance, Liverpool to win the particular Champions League. Right Today There will become probabilities available in inclusion to an individual just have to be able to determine just how very much a person wish in buy to risk. In Case the particular bet is usually a successful 1, after that an individual will obtain your winnings and your current stake. Every Single sport offers the very own established regarding regulations plus the exact same applies whenever it will come to become capable to putting gambling bets upon them. There usually are therefore many regulations that will an individual require to learn, several you probably received’t have got even considered of.

It’s not necessarily simply the particular top groups of which a person may end upwards being inserting wagers upon. The web site does consist of all the the the greater part of well-liked crews like typically the English Premier Little league, La Aleación, German Bundesliga, Serie A plus Flirt 1. Just restricting your gambling possibilities in purchase to all those crews wouldn’t job even though. This recognizes you putting a pair of gambling bets – a win plus a place – therefore it will be a little bit a great deal more expensive than a single bet. A Person may click on about the match up you fancy placing a bet about to take an individual in order to the particular devoted webpage with consider to that event minh huyền.